2 component plant mini flow sensor

email: porter@microflowmeter.com In 2011, Ourengineer Mr Stone return from Siemens and put himself in research andproduction of flow meters with wide flow range, high accuracy, low pressuredrop and high frequency. Now we have super mirco flow meter,oval gear flow meter ,coriolismass flow meter,electromagnetic flow meter,piston flow meter, and Spur gearflow meter, gear pump,gear metering pump. There is no other manufactures whocan produce micro flow meter and many company import this kind of flow meterfrom Japan or America. After we put our micro flow meter into market, the newswas spreaded widely and we got many reputation from our client. We now havesold this flow meter to more than 100 countries which contain wide and differentapplications. Meanwhile our oval gear flow meter has aquired many certificates and filled thevacancy of Chinese market.

2 component plant mini flow sensor

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Ovalgear flow meter is a new type of volumetric flowmeter, in addition to apositive displacement flowmeter with high accuracy, the flow is not sensitiveto other advantages, there are the following advantages: Wide range, usually inthe flow meter is 10: l, and Deep flowmeter is generally 100: 1, or even 1000:1, the accuracy is still above 0.5%, suitable for high pressure flowmeasurement, the maximum pressure can reach 100Mpa, especially suitable for themeasurement of small flow, the minimum measurement limit can be 0.3ml / min ,Less affected by the viscosity characteristics of the medium, suitable for flowmeasurement under various viscosity conditions.

2 component plant mini flow sensor

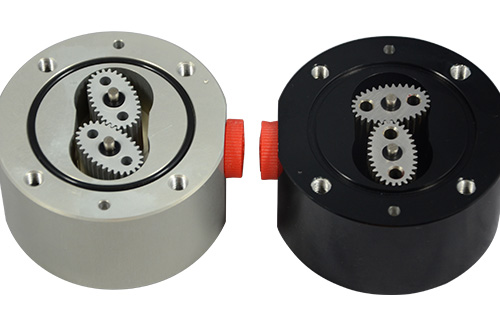

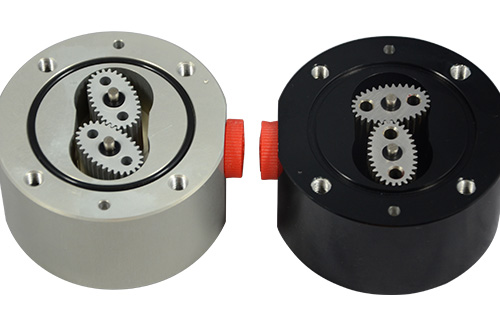

Componentsand principles of the Oval gear flow meter - The measurement part of the flowmeter consists of two intermeshing gears and its housing (metering chamber).The measured medium mass per revolution of the gear is half-moon-shaped 4times, in the mirco flow meter hemispherical volume under certain conditions,as long as the measured gear rotation speed n, we can know the measured mediumflow.

2 component plant mini flow sensor

Technicaldata of CX-M Series micro oval Oval gear flow meter

Model | Flow range | Accuracy | Connection size |

CX-M2 | 0.5~150ml/min | 0.5% | G1/8" |

CX-M3 | 3~300ml/min | 0.5% | G1/8" |

CX-M5 | 5~1000ml/min | 0.5% | G1/8" |

CX-M6 | 0.5~100L/H | 0.5% | G1/4" |

CX-M9 | 6~600L/H | 0.5% | G1/4" |

CX-M12 | 0.3~30L/Min | 0.5% | G1/2" |

CX-M25 | 0.5~100L/Min | 0.5% | G1" |

What are the precautions for the gear flow meter?

1) When the flow exceeds the specified maximum flow rate, the Oval gear flow meter wear increases with the increase of the rotation speed, and the pressure loss increases sharply, should be avoided. Less than the minimum flow, although still able to measure, but the error increases. Flow meter The starting flow is about 2% of the maximum flow, and the normal working flow is preferably 70%-80% of the maximum flow.

2) Deep-rooted flowmeter is used with various viscosity media from 0.3 ~ 100000cps, different viscosity media will affect the range, the following single must be noted

3) The measured liquid temperature should not exceed the specified value, otherwise, the instrument can not work properly, or even stuck, the counter part is easily damaged at high temperatures. Liquid temperature changes will also cause additional errors in viscosity.